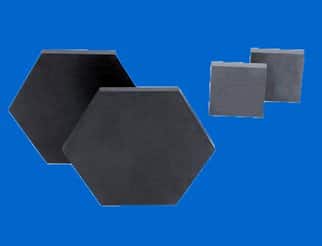

Boron Carbide Plate

Boron carbide is an extremely hard boron-carbon ceramic. Boron carbide has a Mohs hardness of about 9.49, which is the third-highest hardness material after diamond and cubic boron nitride. Because of its high strength, low density, corrosion resistance, high temperature resistant, low thermal conductivity, and high modulus of elasticity, the boron carbide plate is ideal for a wide variety of applications.

Boron Carbide Plate Properties

| Compound Formula | B4C |

| Molecular Weight | 55.26 |

| Appearance | Black |

| Melting Point | 2445℃ |

| Density | 2.1 to 2.7 g/cm3 |

| Electrical Resistivity | 0 to 11 10x Ω-m |

| Poisson’s Ratio | 0.17-0.18 |

| Specific Heat | 950 J/kg-K |

| Tensile Strength | 350 MPa (Ultimate) |

| Thermal Conductivity | 31 to 90 W/m-K |

| Thermal Expansion | 4.5 to 5.6 µm/m-K |

Boron Carbide Plate Applications

-Abrasive field: Surfaces of watches and jewels.

-Refractory materials: As an antioxidant additive in the refractory field.

-Ceramics materials: As materials made of boron carbide products and wear-resistant components used in blasting, sealing, machinery, ships, auto, dies, aviation and aerospace industries.

-Armor tiles: High-density boron carbide armor tiles, bulletproofing seats of helicopters.

-Nuclear industry: Boron carbide is an important material for nuclear applications due to its high absorption cross-section.

-Boriding Agent: Boron carbide is a raw material used in boriding agents. After the treatment, the hardness and the wear resistance of the surface are greatly improved.

-Chemical additives: Because of boron carbide’s good chemical resistance, for producing other boron-containing materials such as titanium boride or zirconium boride.

-Solid fuel: Boron carbide-based propellants for ducted rockets.

Packing of boron carbide

Our boron carbide plate is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Edgetech‘s ceramics

Our advanced ceramics include Hot pressed Boron Nitride (HBN), Pyrolytic Boron Nitride (PBN), Silicon Nitride (Si3N4), Aluminum Nitride (AlN), Zirconia (ZrO2), Alumina (Al2O3), Lanthanum Hexaboride (LaB6), Cerium Boride (CeB6), Silicon Carbide (SiC), Boron Carbide (B4C), etc. Customized and complex ceramic parts are available on request.

Related Products