Zirconia Toughened Alumina (ZTA)

Zirconia Toughened Alumina Ceramics (referred to as composite ceramics, ZTA) has the characteristics of corrosion resistance and chemical stability. Alumina has high hardness and the toughness of zirconia is good. The composite ceramics have the properties of both materials, it has higher flexural strength and fracture toughness at room temperature, and zirconia toughened ceramics have excellent wear resistance, high strength, and hardness.

The performance of ZTA ceramics is better than that of 99 alumina ceramics, and the price is much lower than that of zirconia ceramics. The specific ratio of the two materials can be adjusted according to the application. Typically, ZTA contains 10-20% volume of ZrO2 in alumina. Depending on the percentage of content, the properties of the ceramic can be tailored to suit the application in question.

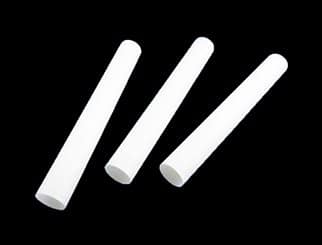

Boron Carbide Parts China is a specialist supplier of zirconia toughened alumina products (Available products: ZTA rods, tubes, disc, seal ring, sheet, plate, etc.) of the highest quality for a wide range of applications.

Zirconia Toughened Alumina Properties

| Chemical Formula | Zr-Al2O3 |

| Density | 4.1-4.38 g/cm^3 |

| Hardness | 1750-2100 Knoop |

| Elasticity | 45-49 x 10^6 psi |

| Flexure Strength | 100-145 ksi |

| Poisson’s Ratio | 0.26 |

| Fracture Toughness | 5-7 MPa m^1/2 |

| Coefficient of Thermal Expansion | 8.0-8.1 x 10^-6 1/C |

| Thermal Conductivity | 20.0-21.0 W/mK |

| Shock Resistance | 325 °C |

| Maximum Working Temperature | 1650 °C |

Specifications of Zirconia Toughened Alumina

| Condition | Unit | ZTA | ||

| Material | — | — | Al2O3/ZrO2 | |

| Color | — | — | White | |

| Density | — | g/cm3 | 4 | |

| Surface Roughness | — | μm | 0.2 | |

| Reflectivity | 0.3-0.4mmt | % | 80 | |

| 0.8-1.0mmt | % | 90 | ||

|

Mechanical | Bending strength | 3-point method | MPa | 700 |

| Modulus of Elasticity | – | GPa | 310 | |

| Vickers Hardness | – | Gpa | 15 | |

| Fracture toughness | IF method | MPa∙m1/2 | 3.5 | |

| Thermal | Coefficient of thermal expansion | 40-400℃ | 10–6/K | 7.1 |

| 80-400℃ | 10–6/K | 8 | ||

| Thermal conductivity | 25℃ | W/(m∙K) | 27 | |

| 300℃ | W/(m∙K) | 16 | ||

| Specific heat | 25℃ | J/(Kg∙K) | 720 | |

| Electrical | Dielectric constant | 1mHZ | – | 10.2 |

| Dielectric loss factor | 1MHZ | Tanx10-4 | 0.2 | |

| Volume resistivity | 25℃ | Ω∙cm | >1014 | |

| Breakdown strength | DC | kV/mm | >15 | |

Zirconia Toughened Alumina Applications:

Where high strength and erosion-resistant material is needed, ZTA ceramics can become the first choice. Industrial components such as valve seals, sleeves, pump pistons, and spraying nozzles are perfectly suited for ZTA.

Other Applications:

-Standoffs

-Insulators

-Probe Bodies

-Bushings

-Fluid Delivery System Components

-Pump Position Sleeves

-Instrument

-Sensor Bulbs

-Impellers

-Analytical instrument Columns

Packing of Zirconia Toughened Alumina Products

Our ZTA products are clearly tagged and labeled externally to ensure efficient identification and quality control. The products are separated by bubble bags for shockproof purposes and finally packed in wooden or carton boxes. Great care is taken to avoid any damage which might be caused during storage or transportation.

Related Products