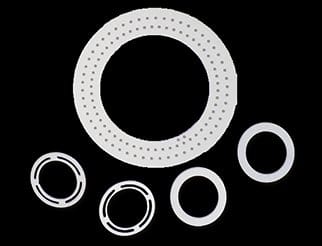

Pyrolytic Boron Nitride Heaters (PBN/PG Heater)

PBN/PG Heater Description

High purity and high-performance pyrolytic boron nitride are used as the substrate for the PBN heating elements. Pyrolytic graphite (PG) is placed on the surface of PBN components by the CVD method as conductor and heater. Depending on different requirements of usage, the PG heating element could be covered by another layer of PBN or just stay open.

As both PG and PBN are extremely pure (99.99% or even higher) and very stable in a vacuum or inert atmosphere, the PBN-PG heating elements could be very durable. It could be heated to 1600℃ in a very short time without emission of any gas component, the chamber is clean when using PBN/PG heaters. These heating elements are ideal products for the semiconductor industry and applications that require high temperature, high vacuum, and high purity.

| Diameter | 0.5” ~4” |

| Power | 150~3000W |

| Max. Working Temp. | 2400 ℃ |

PBN/PG Composite Heating Element Specification

| Item | value | Unit | |

| lattice constant | a:2.504×10-10 c:6.692×10-10 | μ m | |

| density | 2.0-2.19 | g/cm3 | |

| resistivity | 3.11×1011 | Ω·cm | |

| tensile strength(ab) | 153.86 | N/mm2 | |

| bend strength | c | 243.63 | N/mm2 |

| ab | 197.76 | N/mm2 | |

| elastic modulus | 235690 | N/mm2 | |

| Thermo conductivity | “a” direction “c” direction | ||

| (200℃) | 60 2.60 | W/m·k | |

| (900℃) | 43.70 2.80 | W/m·k | |

| dielectric strength(at room temperature) | 56 | KV/mm | |

PBN/PG Heater Advantages

-PBN composite heating element has an operating temperature up to 1600°C.

-High mechanical durability and dimensional stability.

-High thermal shock resistance.

-PBN layer provides electrical insulation.

-Eliminate outgassing and contaminations.

-Thermal gradients can be tailored.

-Chemically inert to almost all metals, liquids, and gas.

-Large variety of PG heater and PGN heater shapes are available.

Packing

As a ceramic material, boron nitride is quite fragile in a lot of cases. Our PBN/AG heater is carefully handled to minimize damage during storage and transportation. Suitable outer boxes and inner cushioning materials are used for PBN products, vacuum packing is also engaged for some of the parts.

Related Products