Alumina Ceramic

Alumina (Al2O3) Ceramic

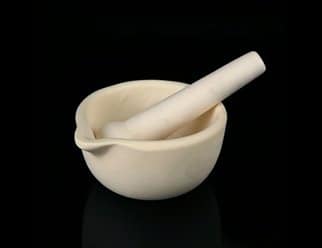

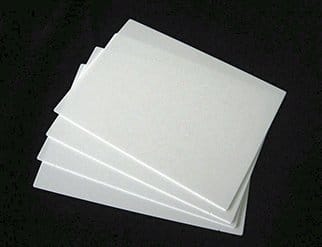

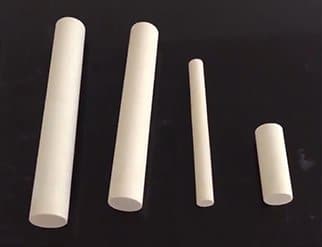

Alumina (Aluminum oxide) has a very high melting point of 2,072 °C and it is extremely hard. Alumina ceramic is the most common technical material and relatively traditional ceramic. High purity alumina has excellent performances in electrical insulation, high chemical resistance, and low thermal expansion. They are used to make parts for CVD, ion implants, photolithography, and semiconductor. Alumina tubes are used for industrial furnaces and thermal couple protectors. Alumina ceramics are ideal for products such as injector tubes, gas nozzles, and insulators traditionally. The high hardness makes alumina an ideal material for abrasive, grinding media. Alumina mortars and pestles are widely used in laboratories for grinding.

Alumina Ceramics Properties

-Insulation

-Thermal insulation

-Wear resistance

-Corrosion resistance

-Resistance to plasma etching

Alumina Ceramic Application

-Spare parts for pan-semiconductor equipment (manufacturing equipment such as LCD and LED)

-Insulation

-Wear parts

-General machinery, hydraulic components

-Used as injector tubes, gas nozzles, and insulators.

-High-temperature situations & a protector for high-temperature thermal couples.

Boron Carbide Parts China, Advanced Ceramics Division is a leading supplier of ceramic materials. We offer alumina products of high purity and at a competitive price.

Our advanced ceramics include Hot pressed Boron Nitride (HBN), Pyrolytic Boron Nitride (PBN), Silicon Nitride (Si3N4), Aluminum Nitride (AlN), Zirconia (ZrO2), Alumina (Al2O3), Lanthanum Hexaboride (LaB6), Cerium Boride (CeB6), Silicon Carbide (SiC), Boron Carbide (B4C), etc. Customized and complex ceramic parts are available on request.