Boron Nitride Composite Ceramics AlN-BN

Boron nitride material could be physically enhanced by adding some other ceramics, such as CaO (HBN), ZrO2(ZSBN), or AlN (AlN-BN), high purity boron nitride could withstand higher temperatures in an inert atmosphere than the composite/enhanced ceramics. However, the enhanced BN usually has better wear resistivity and better performance in the air.

Boron nitride composite ceramics are manufactured by a transitional plastic phase process. The relative density of the hot-pressed composite decreases as the boron nitride content increases, but 30% of the boron nitride can be obtained in more than 99% of the aluminum nitride. Though materials such as quartz are not available in high-temperature gas atmospheres, boron nitride-aluminum nitride composite ceramic gears provide reliable drive performance.

-High hardness, excellent wear resistance

-High mechanical strength, high thermal conductivity

-Provide a reliable driving force for gears

Boron Nitride Composite Ceramic BN-AlN Specifications

| Name | BN-AlN | |

| Compositions | BN+AIN | |

| Binder | AlBO3 | |

| Density | g/cm3 | 2.5-2.6 |

| 25°C Volume Resistivity | Ω·cm | >1014 |

| Max. Service Temp. (°C) | Oxygen | 900 |

| Inert Gas | 2100 | |

| High Vacuum | 1900 | |

| Flexural Strength | Mpa | 130 |

| Compressive Strength | Mpa | 250 |

| Coefficient of Thermal Expansion | 10-6/K | 4.5 |

| 25-1000°C | ||

| Thermal Conductivity | W/mK | 60 |

Boron Nitride Composite Ceramic BN-AlN Applications

-Insulation

-Semiconductor equipment components

-Molded glass fixture material

-Used as bearings and gears

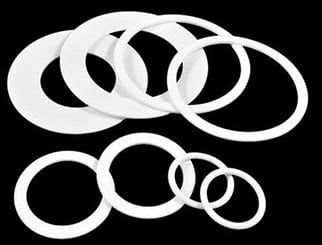

Available Boron Nitride Composite Ceramic BN-AlN products: Disc, sheet, plate, tube, ring, rod, Insulators, and other machined parts.

Packing

Our Boron Nitride Ceramic BN-AlN is always carefully handled to prevent damage during storage and transportation and to preserve the quality of our product in its original condition.

Related Products