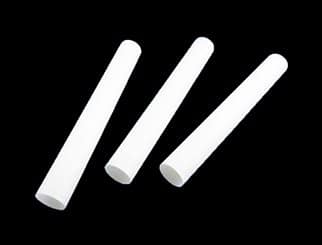

Zirconia Ceramic (ZrO2)

Zirconia Ceramics (ZrO2)

Zirconia ceramic, also known as zirconium dioxide (ZrO2) ceramic, is a new type of high-tech ceramic, it has the highest toughness and strength at room temperature of all the advanced ceramic materials. It also has excellent thermal insulation and low thermal conductivity.

Zirconia Ceramic has a high melting point and boiling point, high hardness, is an insulator at room temperature and has electrical conductivity at high temperature, and the following excellent properties.

-High thermal expansion (α = 11 x 10-6 / K)

-Excellent thermal insulation / low thermal conductivity (2.5 to 3 W mK)

-Very high crack growth resistance, high fracture toughness

-Ability to conduct oxygen ions (for measuring oxygen bias in a λ probe)

Pure ZrO2 products often undergo a phase change during the production process (the cooling process from high temperature to room temperature) and generate cracks or even cracks along with the volume change. However, when appropriate stabilizers (such as Y2O3, MgO2, CaO, CeO2, etc.) are added, the phase transition temperature can be reduced, and the high-temperature stable c-ZrO2 and t-ZrO2 phases can also be stable or metastable at room temperature. When enough stabilizer is added, the high-temperature stable c-ZrO2 can be kept until the room temperature does not undergo a phase change. Therefore, the conventional zirconia ceramics are zirconia ceramics added with different stabilizers, rather than pure zirconia products. The addition of different content and types of stabilizers can make zirconia ceramics used in different fields.

-Structural ceramic parts, such as dispersing and grinding media, nozzles, ball valve ball seats, molds, miniature fan shafts, fiber optic pins, fiber optic sleeves, cutters, watch cases and straps, ball bearings, and other room-temperature wear-resistant zero devices

– Functional ceramics parts, Induction heating tubes, refractory materials, heating elements

-Zirconia ceramics have sensitive electrical performance parameters and are mainly used in the fields of oxygen sensors, solid oxide fuel cells (SOFC), and high-temperature heating elements.

-ZrO2 has a high refractive index (N-21 ^ 22). Adding certain coloring elements (V2O5, MoO3, Fe2O3, etc.) to the ultrafine zirconia powder can make it into a colorful translucent polycrystalline ZrO2 material, that can be made into various decorations.

-In addition, zirconia is widely used in thermal barrier coatings, catalyst carriers, medical treatment, health care, refractory materials, textiles, and other fields.

Boron Carbide Parts China, advanced ceramics division is a leading supplier of ceramic materials. We offer zirconia products (partially stabilized zirconia & fully stabilized zirconia) of high quality and at a competitive price.