Pyrolytic Boron Nitride VGF Crucible, PBN VGF Crucible

Pyrolytic Boron Nitride (PBN) VGF Crucible is produced by the CVD process to create its solid body and all the boron nitride crystals grow parallel to the surface on which the vapor is deposited. Due to the nature of the CVD process, thick wall products (>3mm) are usually not available. For PBN VGF crucibles, the typical thickness is 0.8~1.5mm.

PBN products are extremely pure, as the purity of gas material is easier to be controlled. Typically, PBN products have a total impurity of <100 ppm, which means the purity is no less than 99.99%. With such a high purity level, PBN products are ideal products for semiconductor industries & vacuum systems.

With its high density and purity, PBN is becoming a widely used material in vacuum processes. The CVD process gives this pyrolytic boron nitride an almost perfect layered structure, which leads to anisotropic thermal conductivity, making it an ideal material to make crucibles for crystal growing. The vertical gradient freeze method (VGF) is a popular technology for crystal production and the PBN VGF crucibles are specialized consumption for this type of process.

The pyrolytic boron nitride crucibles EDGETECH could supply are custom produced from our CVD furnace with high purity material. Dimensions of PBN crucibles are limited to 12″ Dia. x 12″ H, by equipment size.

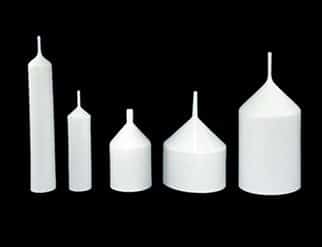

We provide custom PBN crucibles and VGF / LEC / Conical / MBE / OLED crucibles.

Packaging

As a ceramic material, boron nitride is quite fragile in a lot of cases. The Pyrolytic Boron Nitride (PBN) VGF crucibles are usually held in plastic bags by vacuum, and protected with heavy foam.

Related Products