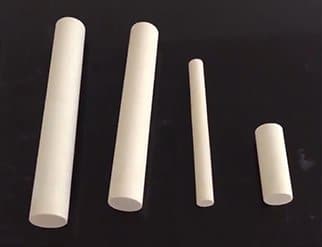

Alumina Rod

Alumina ceramic is the most common technical material and relatively traditional ceramic. High purity alumina has excellent performances in electrical insulation, high chemical resistance, and low thermal expansion. Alumina Rod is used to making parts for CVD, ion implants, photolithography, and semiconductor.

Specifications of Alumina Rod

| Size | Diameter: 1~100mm |

| Material | Al2O3 |

| Purity | 99%-99.8% |

| Density | 3.8~3.9 g/cm3 |

Specifications of Typical Alumina Ceramics

| Composition | UNIT | AL97 | AL98 |

| AL2O3 Purity | % | 97 | 99.8 |

| Color | N/A | White | Ivory |

| Tensile | Kpsi | 30 | 32 |

| Flexural | Kpsi | 55 | 60 |

| Compressive | Kpsi | 300 | 330 |

| Density | g/cc | 3.70 | 3.92 |

| Hardness | HV, GPa | 13.8 | 18 |

| Thermal Conductivity | W/ (m K) | 25 | 32 |

| C.O.T.E. | In / In°C (x107) | 77 | 78 |

| Working temperature | °C | 1500 | 1750 |

| Dielectric Constant | N/A | 9.5 | 9.8 |

| Volume Resistivity | Ohm-cm | >1014 | >1015 |

| Dielectric Strength | KV/mm | 16 | 20 |

The above chart just demonstrates the typical properties of common alumina ceramic we use to produce our alumina parts. Please notice that the properties of customized alumina parts vary due to different processing. Boron Carbide Parts China, Advanced Ceramics Division provides alumina products according to your specified instruction or does its best to meet requirements.

Alumina Rod Application

-Spare parts for pan-semiconductor equipment (manufacturing equipment such as LCD and LED)

-Insulation

-Wear parts

-General machinery, hydraulic components

-Used as injector tubes, gas nozzles, and insulators.

-High-temperature situations & a protector for high-temperature thermal couples.

Packing of Alumina Rods

As a ceramic material, Alumina Rod is quite fragile in a lot of cases. Our Alumina Ceramics are carefully handled to minimize damage during storage and transportation. Suitable outer boxes and inner cushioning materials are used, and vacuum packing is also engaged for some of the parts.

Related Products