Magnetism is the basic property of matter as well as force, heat, electricity and light. Materials with ferromagnetism are usually called magnetic materials. The biggest characteristic of magnetic materials is the hysteresis behavior, that is, the magnetization M changes with the external magnetic field. When H returns from a certain state to zero, M still maintains a certain size. Only when the magnetic field is applied in the opposite direction M drops to zero, so that the reciprocal change of M with H is a loop instead of a single curve.

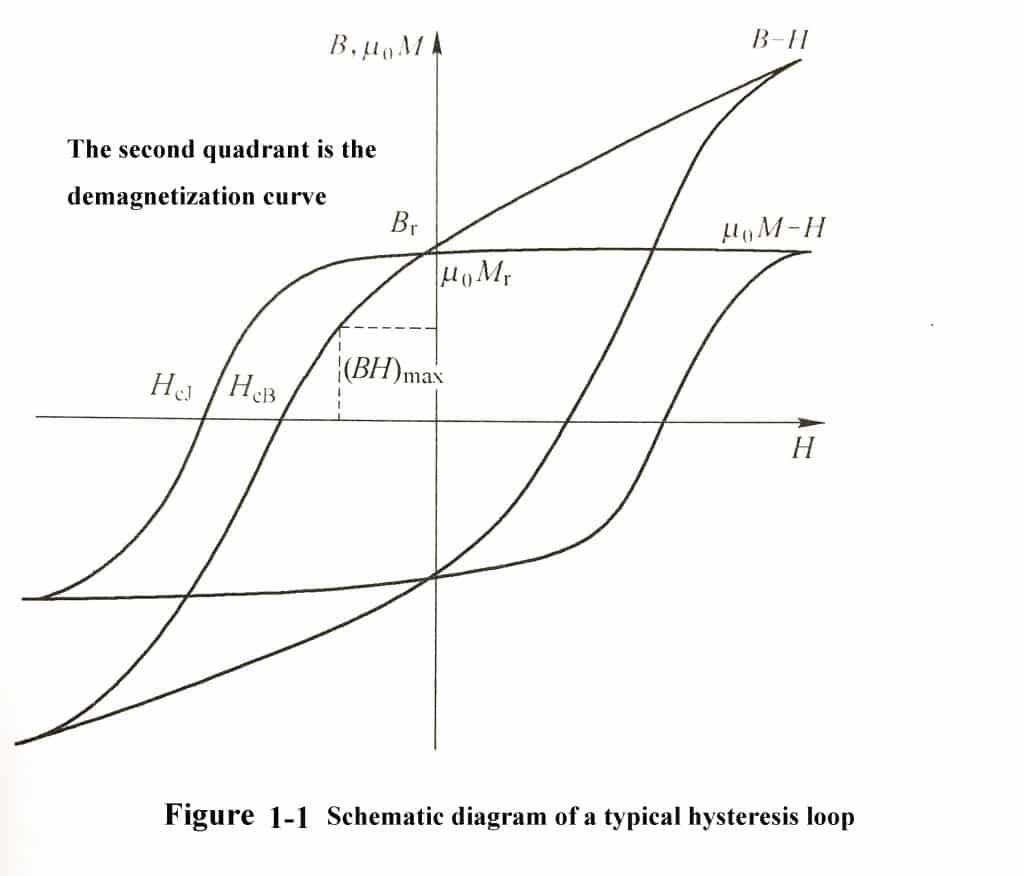

Figure 1-1 shows a schematic diagram of a typical hysteresis loop.

The main parameters describing the characteristics of the hysteresis loop are:

(1) Residual magnetic induction Br, (or residual magnetic polarization Jr=AMr) (remanent magnetism for short) is the magnetic flux density when the magnetic field H=0 in the magnet;

(2) The coercive force HcB (or intrinsic coercive force HcJ) is the reverse magnetic field H necessary for the magnetic flux density B=0 (or magnetic polarization J=0);

(3) The maximum magnetic energy product (BH)max (magnetic energy product for short) is the magnetic energy product with the largest product of B and H on the demagnetization curve (the second quadrant of the hysteresis loop).

Materials with different hysteresis loops are used in different application fields. These materials are generally divided into two categories: one is soft magnetic materials with low coercivity (HcJ<100A/m), and the other is coercivity. Permanent magnet materials with large force (also called hard magnetic materials) (Hc>1000A/m).

The characteristic of the permanent magnet is that after being magnetized by the external magnetic field, the magnetic field can be kept stable for a long time after the external field is removed. The most comprehensive criterion for the performance of permanent magnetic materials is the shape of the demagnetization curve under various external conditions (external magnetic field, temperature, time, radiation, vibration, etc.), but for simplicity, usually only the above mentioned Three parameters and its stability are measured: the size of the magnetic energy product (BH)max, which characterizes the ability of permanent magnets to provide magnetostatic energy, that is, in the case of meeting the same magnetic field value and spatial range, (BBD) large materials are used Less material; the greater the residual magnetization Br, the greater the magnetic field strength that the magnet may provide to the space; and the material with a large HcJ has strong anti-interference ability. Therefore, the higher the above three parameters, the better the magnetic properties of the permanent magnet. The temperature stability of permanent magnetic materials mainly refers to the temperature coefficient and irreversible loss of the material. The temperature coefficient (or reversible temperature coefficient) refers to the percentage of reversible change in residual magnetism or coercive force when the temperature changes. The irreversible loss refers to the rate of change of the open-circuit magnetic flux starting from room temperature and returning to room temperature after heating or cooling. For permanent magnetic materials, the smaller the absolute value of the temperature coefficient and the irreversible loss, the better.

We mainly provide rare earth permanent magnets, including neodymium iron boron magnets and samarium cobalt permanent magnets.